We are your specialist for

Solar sludge drying

- Uncompromising quality

- Efficient technology

- Worldwide experience

Sewage sludge is produced as a waste product in sewage treatment plants and contains water as well as organic and inorganic components. The drying of sewage sludge is a critical process step that is important for both ecological and economic reasons. By reducing the water content, the volume of sewage sludge is reduced, which lowers the costs for transportation and disposal. In addition, drying enables the sewage sludge to be used further, for example as fertilizer in agriculture or as fuel in specialized plants.

The world’s largest solar sludge drying plant in Nicaragua was designed and conceived by us. Our process technology leads the market in the field of solar sewage sludge drying in terms of efficiency, reliability and ease of use.

TechnologyWhile conventional sludge dryers have a very high energy requirement – over 800 kWh per tonne of water removal – the WendeWolf® system only requires 20-30 kWh of electricity. The remaining energy share is supplied by the sun in the form of free radiant energy. The sun’s rays warm the surface of the sludge. This leads to an increase in the water vapor pressure in the sludge. The increase in pressure causes water molecules to be expelled into the surrounding air. Water is also extracted from the sludge at night and in winter – just like in nature when a road dries after the rain. Of course, it’s much quicker in the sunshine!

Interested?

Contact us for more information or a price quote!

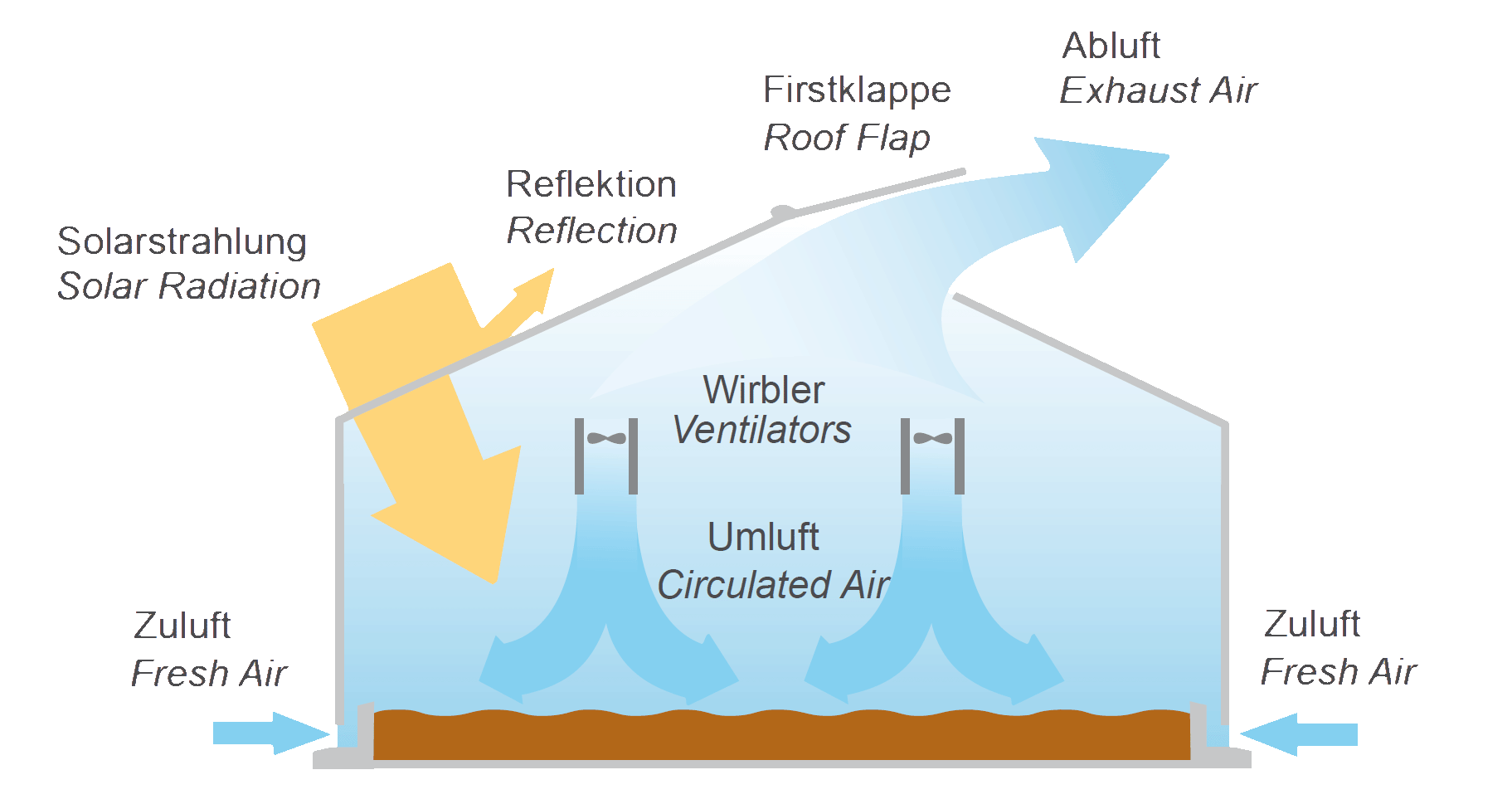

The main energy source for the solar sludge dryer is the short-wave radiation energy of the sun. This hits the dark sludge surface through the transparent building envelope and heats it up. This increase in temperature causes the water vapor pressure in the sludge to rise and expels the water molecules into the layer of air above.

In our latitudes, the solar radiation energy per year corresponds to an amount of energy of around 1000 to 1200 kWh per m² and year. This allows – purely mathematically – 1450 to 1750 kg of water per m² and year to evaporate.

Energy studies on greenhouses show that around half to two thirds of this potential can be utilized per m² of floor space, i.e. around 700 – 1200 kg of water removal per m² of active drying area; this is also particularly dependent on the selected operating mode of the solar drying system (variable or constant input of the filter cake).

Over 200 WendeWolfs have been installed worldwide. It has been shown that dewatering the sludge to a dry substance content of around 20% is usually a cost-efficient pre-treatment.

With a sludge input of 5% DS and a targeted degree of drying of 70% DS, approx. 5 times the drying area is required compared to a sludge input of 20% DS and an achieved degree of drying of 70% DS.

| Example (A): Entry with 5% DS | Values |

|---|---|

| Dry substance | 500 tons/a |

| Degree of drainage | 5% |

| Sludge entry | 10’000 tons/a |

| Target degree of drying | 70% |

| Removal of granulate | 715 tons/a |

| Water evaporation | 9’285 tons/a |

| Example (B): Entry with 20% DS | Values |

|---|---|

| Dry substance | 500 tons/a |

| Degree of drainage | 20% |

| Sludge entry | 2’500 tons/a |

| Target degree of drying | 70% |

| Removal of granulate | 715 tons/a |

| Water evaporation | 1’785 tons/a |

We recommend the following:

The sludge should be mechanically dewatered and puncture-resistant. For drying, it is irrelevant whether the pre-treatment produces a stabilized or digested sludge. For municipal sewage sludge, dry matter contents from 20% have proven to be sufficiently dewatered, but some plants are operated far below this.

When introducing liquid sludge, we recommend tests so that the formation of granules can be observed.

If possible, the sludge should be delivered to the hall directly from the press or decanter discharge; it should not be stored outside the drying halls for long periods of time. If the dewatered sludge is stored for a longer period of time, there is a risk that it will go into an anaerobic state, which not only worsens its rheological properties but also causes bad odors to develop. It should not be sanitized with unslaked lime. The high pH value results in high concentrations of NH³ in digested sludge. This can lead to impermissible emissions.

Without air movement, a moist boundary layer forms on the surface. This moist, saturated layer of air leads to a reduction in evaporation performance, which should be avoided. It is therefore important to regulate the climate and air movement in the drying halls.

The supply air enters through side openings in the upright walls. The exhaust air escapes through the ridge ventilation flaps (chimney effect), as moist, warm air is lighter than dry air. The tube fans (swirlers) blowing downwards at an angle generate an air flow on the sludge surface and thus additionally support the drying process.

The exchange of humid indoor air for drier outdoor air is ensured by the WendeWolf

Software regulated. The air water content and the ideal drying climate are determined on the basis of the measured temperature and relative humidity. As soon as an adjustable threshold value is exceeded, the ridge flap opens and the lighter moist air escapes upwards and draws in drier air through the side openings.

This ensures an ideal climate inside the drying halls at all times and optimizes the water evaporation rate.

Depending on the type and amount of waste heat, an auxiliary heating system can be integrated. We have already implemented the following heating systems:

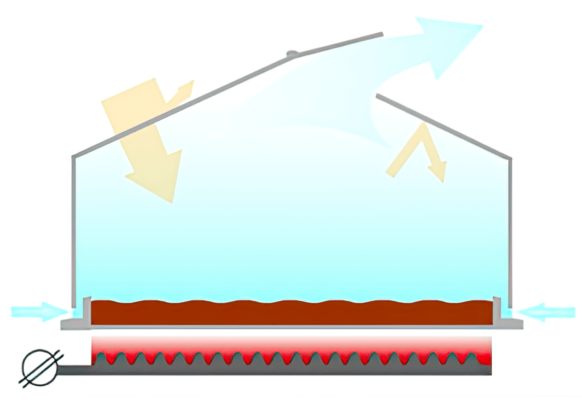

If a lot of heat is available, it can be used to heat the floor slab. For this purpose, plastic pipes are laid between the reinforcement of the floor slab. A common type of heating that is widely used in large halls.

The sludge is heated from above by the sun’s rays, and the underfloor heating also heats the sludge from below.

However, the more radiation there is, the warmer the sludge gets from above and the less heat the floor heating can give off.

Underfloor heating is therefore particularly efficient in winter, but there is usually little waste heat available.

The temperature level of the waste heat can be below 50°C.

Underfloor heating uses the available waste heat very efficiently. However, the investment costs are very high compared to other heating options.

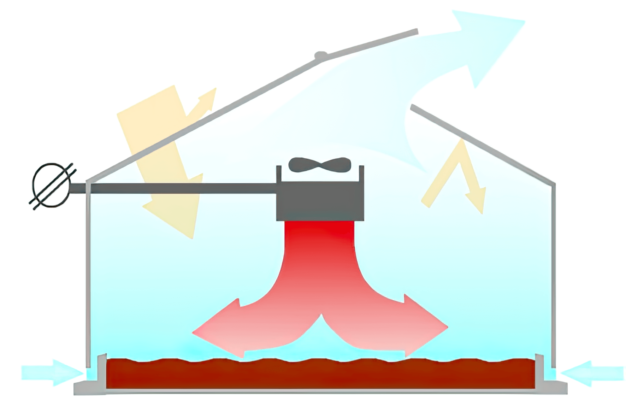

Hall air heating is provided if there is little waste heat available, or in combination with floor heating if this cannot utilize all of the waste heat. The hall air heating system blows warm air onto the sludge surface, indirectly heating the sludge. The heated air can also remove more water.

The energy required for evaporation heat is supplied to the sludge via the air, while at the same time some of this supplied heat is lost via the building envelope – especially in winter and at night.

A hall air heating system is characterized by high flexibility with strongly fluctuating waste heat, simple maintenance and a low investment.

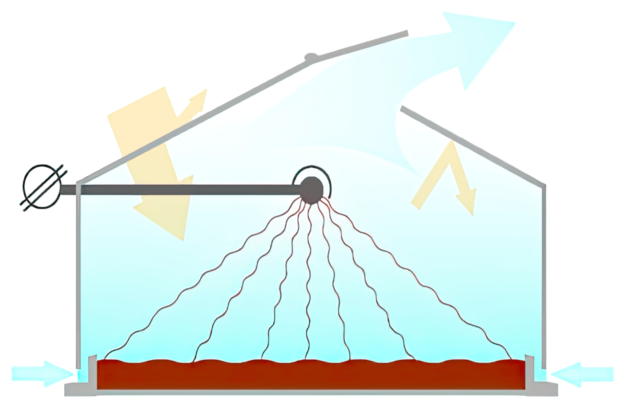

Dark radiators are operated with excess digester gas, which heats the sludge directly. Dark radiators consist of a gas burner and a metal tube in which the combustion gases are fed.

The surfaces of these dark radiators reach around 250 °C and emit their energy in the form of long-wave infrared radiation.

The so-called dark radiators are used as IR radiators in many industrial halls. The wavelength emitted by dark radiators is in the low infrared range. It consists of electromagnetic waves which, like the sun’s rays, penetrate the atmosphere almost loss-free. Only when they hit an absorbent body, in our case the sludge, is the radiation absorbed and heats this body directly.

A heating system with dark radiators is very flexible, easy to maintain and requires a low investment, similar to an indoor air heating system.

In addition to a rapid exchange of air in the hall, it is important that the particles that have already dried on the surface are exchanged as quickly as possible for the moist particles below. The more frequently and intensively the surface of the moist sludge particle comes into contact with unsaturated air, the greater the evaporation rate.

In addition to a rapid exchange of air in the hall, it is important that the particles that have already dried on the surface are exchanged as quickly as possible for the moist particles below. The more frequently and intensively the surface of the moist sludge particle comes into contact with unsaturated air, the greater the evaporation rate.

Turning the filter cake as evenly and frequently as possible is crucial for the speed of water discharge!

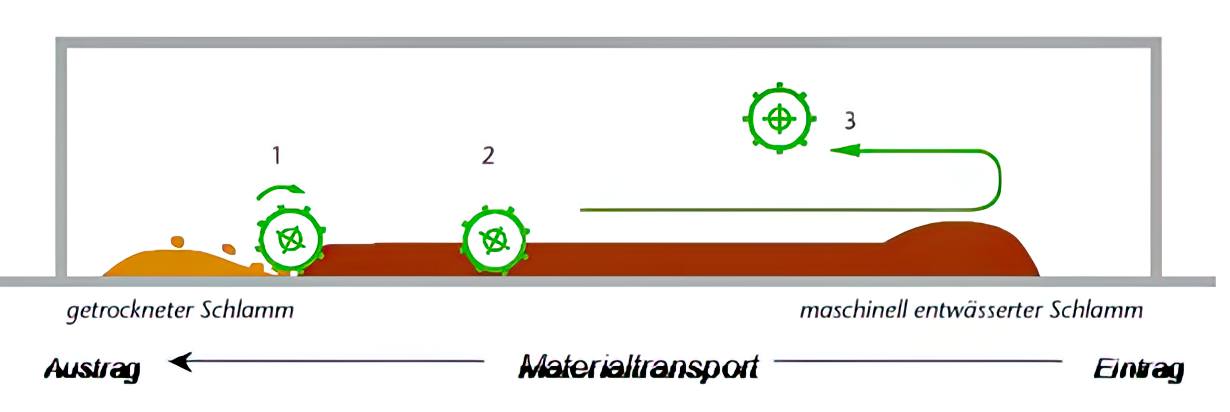

The WendeWolf® turns and mixes the fed filter cake evenly across the entire width of the hall. This ensures good aeration of the dry goods, has a positive effect on water discharge and prevents the formation of odors.

The large turning drum with the patented turning tools guarantees that a sludge bed with a layer thickness of over 40 cm is turned evenly and reliably. The dry goods are shifted by approx. 60 cm per turning process. As this shifting direction is freely selectable, the length of time the dry material remains in the machine can be determined by the working direction of the WendeWolf®.

With the WendeWolf® it is therefore possible to operate the drying system in a batch or continuous process. No changes to the drying system are required to switch between these two operating variants.

In this way, the sludge is moved approx. 60 cm from the feed side to the discharge side of the drying hall per pass. The throughput rate of the sludge through the drying hall can therefore be determined by the number of turning processes.

Over 180 WendeWolfs have been installed worldwide. It has been shown that dewatering the sludge to a dry substance content of around 20% is usually a cost-efficient pre-treatment.

With a sludge input of 5% DS and a targeted degree of drying of 70% DS, approx. 5 times the drying area is required compared to a sludge input of 20% DS and an achieved degree of drying of 70% DS.

| Example (A): Entry with 5% DS | Values |

|---|---|

| Dry substance | 500 tons/a |

| Degree of drainage | 5% |

| Sludge entry | 10’000 tons/a |

| Target degree of drying | 70% |

| Removal of granulate | 715 tons/a |

| Water evaporation | 9’285 tons/a |

| Example (B): Entry with 20% DS | Values |

|---|---|

| Dry substance | 500 tons/a |

| Degree of drainage | 20% |

| Sludge entry | 2’500 tons/a |

| Target degree of drying | 70% |

| Removal of granulate | 715 tons/a |

| Water evaporation | 1’785 tons/a |

We recommend the following:

The sludge should be mechanically dewatered and puncture-resistant. For drying, it is irrelevant whether the pre-treatment produces a stabilized or digested sludge. For municipal sewage sludge, dry matter contents from 20% have proven to be sufficiently dewatered, but some plants are operated far below this.

When introducing liquid sludge, we recommend tests so that the formation of granules can be observed.

If possible, the sludge should be delivered to the hall directly from the press or decanter discharge; it should not be stored outside the drying halls for long periods of time. If the dewatered sludge is stored for a longer period of time, there is a risk that it will go into an anaerobic state, which not only worsens its rheological properties but also causes bad odors to develop. It should not be sanitized with unslaked lime. The high pH value results in high concentrations of NH³ in digested sludge. This can lead to impermissible emissions.

If sewage sludge or dewatered filter cake is stored without further treatment or aeration, bad odors are known to arise.

Our years of experience with differently pre-treated sludges show that the Wende-Wolf process prevents the development of such bad odors during the drying process.

This advantageous behavior is due to the full-surface aeration of the sludge during turning. Aerobic sludge does not stink! Only when the sludge enters an anaerobic state do bad odors arise.

When operating according to our specifications, we therefore guarantee that odors are consistently avoided during the drying process.